Metalenses

Optical design and simulations, and dealing with systems complexity

European Photonics Industry Consortium (EPIC) recently hosted a seminar on optical designs and simulations.

Oliver Faehnle, Head, Optics Fabrication, OST University of Applied Sciences, Switzerland, and co-owner, Pandao, presented on modelling of optical fabrication chains during optical design.

Modelling optical fabrication chains

Modelling of optical fabrication chains depends on performance, optical system design, fabrication chain design, and production. It also needs human interaction. Today, there are over 360 optical fabrication technologies.

Today, you need to design for best performance, do fab chain design after optical design has been finished, and check whether fab feedback comes too late. The next stop is to balance performance and generation. We need to be modelling best fab chain. We also need instant risk and cost impact analyses during optical design.

Pandao provides optical purchasing that cuts down vendors quotes by 30 percent, minimize risk of vendors failure, and enables vendors audits. For optical production, it cuts down 20 percent on fab chains cost, does fab chain marketability analysis, enables capacity steering with one click. For optics design, it cuts down development time by factor of 2, cuts down number of meetings, and does cost impact analysis of design parameters. It also provides the necessary training for optics fab engineers.

Dealing with optical systems complexity

Emilie Viasnoff, Business Development Director, Optical Solutions Group, Synopsys, presented on how to deal with optical systems complexity?

Optics and photonics are getting from the device level to the system level. Synopsys’ driver has been consumer optical systems. Other drivers include automotive optical systems, AR/VR/MR optical systems, and aerospace and defense optical systems. We are dealing with system complexity and optimization.

AR/VR/MR is an emerging application with cutting-edge challenges and system-level constraints. AR/VR systems are collection of complex components: displays using microLEDs, holographic optical element and diffraction optical element HOE/DOE, sensors for head tracking, eye tracking, gesture tracking. There is still a long way to go despite extraordinary investments, and many important industry players.

According to IDTechEx, ‘software is nearly there, but hardware has many hurdles to overcome.’ In optics, there is bottleneck with combiner and compact camera optics. In display, there are issues with resolution and full color. In sensors, there are the emerging technologies in eye tracking and time-of-flight cameras.

For great AR/VR/MR systems, you need a great chip that is AI-enabled, fully-optimized optics, great microdisplay that can provide great images, and great cameras, leveraging metalenses. You need a simulation platform to design and test this complex system.

Synopsys Optical Platform consists of CODE V, LightTools, RSOFT, and LucidShape family. Application areas covered include imaging systems, displays including AR/VR, ADAS, and aerospace and defense. Synopsys design and simulation workflow for waveguide AR glasses includes a parametric bidirectional scattering distribution function (BSDF) as link between RSoft and LightTools.

You can also co-simulate the image quality, setting the interoperability stage for ultra-small and smart cameras. CODE V IMS analysis can understand image quality. LightTools stray light simulation can check ghost image from lens and flare caused by mechanism and sensor.

Synopsys offers design through manufacturing simulation. The simulation flow quantifies manufacturing impact on device performance. Here, metalenses are subject to patterning effects such as shape, shifted size, sidewall angle, and pillar size.

Optics have evolved to more complex systems, especially in consumer applications, such as cameras, AR/VR/MR, ADAS and A&D. Designing these optical systems needs a paradigm shift toward comprehensive simulations platforms.

Synopsys has a comprehensive portfolio to design, optimize and test, end-to-end, optical systems. Our optical design platform for multi-scale simulations is tied to Synopsys electronics platform. Beyond optics, you can go at the system-level with more simulations.

Meta optics design

Lieven Penninck, founder, PlanOpSim, talked about meta optics design software and services. The future is about nano-enabled components. Higher performance gets even more simplified, and there are miniaturized new applications. Design is costly, complex, and time consuming.

PlanOpSim supplies R&D tools to engineers and scientists that allow to unlock the maximum benefit of flat optics in a user friendly way. It offers dedicated meta-surface UI and design workflow, and high-speed and large area simulation. It also offers multi-scale simulations from nano to macroscale.

Meta-surface design workflow takes care of system model, library building, component design, ODA and system analysis, etc. An example of metalens design was design of a metalens with diffraction limited focusing and NA 0.55 for 632nm.

For meta atom optimization, there is a full maxwell solution using rigorous coupled wave analysis. Meta lens performance analysis looks at physical optics regime, flexible and fast parameter variations, direct output to manufacturing, and seamless integration to full wave calculation. Overlapping domain analysis accounts for the interaction of meta atom with neighboring structures. Local calculation avoids memory restriction of full wave calculation. ODA1 (order 2) beta release was in Nov. 2023.

Overlapping domain analysis improves meta-surface calculation accuracy, and is 18x faster than full wave calculation. PlanOpSim will be starting multi-project wafer service very soon, such as meta surface PDK. You can submit meta surface designs for manufacturing from PlanOpSim. Supported wavelength 940nm and size up to 5×5 mm.

This entry was posted in AR/VR, Automotive, Displays, Electronic materials, Electronics, Metalenses, Optical components, Optical networking, Optical transceivers, Photonics, Semiconductor materials, Semiconductors, Silicon photonics, Smart glasses and tagged Metalenses, Optical designs.

Optical metamaterials and metalenses offer novel functions

European Photonics Industry Consortium (EPIC) organized a technology meeting today on metamaterials and metalenses. Corning wafer process solution pairs Corning laser dicing and Dynatex mechanical breaking technology, was a message by the lead sponsor.

Optical metamaterials and metalenses offer many novel functionalities, such as super-resolution imaging, negative optical refraction, beam shaping, and steering. But what is their technology readiness level? In this online meeting, we are going to review the process of industrial adaption of these futuristic technologies in the field and learn from the industry leaders about the first commercially available products comprising metamaterials and metalenses.

Tunable metasurfaces

Junghyun Park, Principal Researcher, Samsung Advanced Institute of Technology (SAIT), South Korea, presented on tunable metasurfaces and its applications. LiDAR has apps in autonomous driving, improving AR/VR, gesture sensing, etc. It can be scanning or non-scanning. Mobile LiDar is present in mobiles, such as flash, spot array, and scanning. Flash has whole area illumination, spot array allows DoE-based spots, etc. Metasurfaces are thin two-dimensional metamaterial layers that allow or inhibit the propagation of electromagnetic waves in desired directions.

When LiDar meets the metasurface, we can get active metasurface. Metamaterials are artificial materials with properties unobtainable in future. Metasurfaces are active vs. passive. We change the control signal for spatio-thermal functions in active. Indium tin oxide is a gate-tunable material. Plasma frequency is tunable. Two control parameters enable complex modulation, Vt and Vb, or top and bottom gates. We can also have solid state beam steering for LiDar apps.

Optical manufacturing

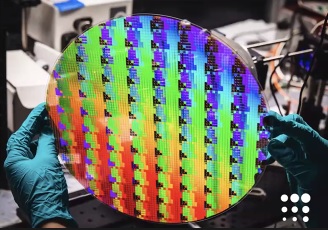

Gauthier Briere, Product Marketing Manager, Applied Materials, presented on optical manufacturing services for metalenses and metaoptics. Its Engineered Optics Group makes optical devices. EO product focus is on waveguides for AR glasses and flat lenses for near IR on 300mm transparent substrate.

Metaoptics is a disruptive technology that you didn’t see coming! Metalenz and STMicroelectronics delivered the world’s first optical metasurface for consumer electronics devices. Metaoptics are available in small-, medium-, and large-size pillars. Metaoptics are in 10s to 10K lens/devices per wafer. Pillar full-wafer CD uniformity control or CDU full wafer 3o- <12nm can be achieved across design-rule CD range.

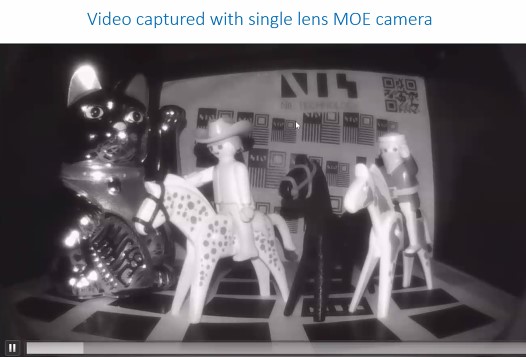

MOE camera

Niklas Hansson, Head of Application Engineering, NIL Technology, presented on NILT’s Single Lens (1 MOE) camera. NIL has meta optical elements (MOEs) and masters for displays (AR/MR). MOEs are for illumination and receiver optics for ToF, LiDar, driver monitoring, and eye tracking. NILT has six class 10-100 cleanrooms.

MOE is a lens technology with potential to disrupt optics used for sensing and imaging. NILT provides custom-made solutions with MOE. Light goes into lens, straight through. We are working on improving efficiency. Single-lens MOE camera eliminates abberation. We have camera with single lens (MOE) surface. We can eliminate field curvature, coma, and astigmatism. Performance is similar to refractive camera. We used pure pillars such as silicon-on-glass, and free form meta-atoms. It uses electron-beam lithography.

Transforming optics and sensing

Rob Devlin, Co-Founder and CEO, Metalenz, presented on meta-optics: transforming sensing and moving optics into semiconductor foundry. Metalenz is transforming optical sensing, and is first fabless semiconductor optics company. It is a spin out from Harvard University, commercializing foundational metasurface IP. It designs and sells meta-optics targeting 3D sensing in consumer electronics and automotive markets.

Metasurface optics manufacturing process enables optics manufacturing in semiconductor foundries. There is a single semiconductor layer used, along with standard semiconductor materials. In 2011, the metasurface came into being. We are sensing disruptions, and enabling proliferation of optical sensing. First Metalenz devices are in the market now. It replaces existing optics in ST FlightSense ToF module.

An example of Gemini was shown, the world’s first dual pattern 3D projector. One projector gives dual patterns. Another example is PolarEyes, that is fit for any form factor. Apps include medical imaging, edge detection, biometric authentication, high-resolution 3D shape reconstruction, etc. Metalenz is enabling supply chain consolidation and proliferation of advanced sensing.

In another sponsor message, PHASICS proposes SID4-sC8 wavefront sensor for the metasurfaces characterization, using quadriwave lateral shearing interferometry or QWLSI technology.

Metalens manufacturing

Patrick Schuster, Process Engineer at EV Group, presented metalens manufacturing using nanoimprint lithography. It has EVG nanoimprint lithography solution for step and repeat or S&R mastering to wafer level imprint. It is an offering to help customers accelerate the deployment of nanoimprint lithography (NIL) in high-volume manufacturing. SmartNIL enables replication of different geometries/orientation and dimensions.

We can design to imprint and provide pattern fidelity. NIL at EVG does wafer-level based manufacturing, provides SmartNIL technology and open materials platform. NILPhotonics Competence Center is an innovation incubator. It is currently looking for a mastering partner, along with new materials. EVG-Toppan has a whitepaper on manufacturing of metalenses using NIL.

Challenges and opportunities

Lieven Penninck, Founder, PlanOpSim, presented a view on opportunities and challenges for design of metalenses and metasurfaces. There are bottlenecks in metasurface design. We need integration to system level, have fast large-area design, and design for manufacture is in an embryonic stage.

For system integration, we have to optimize using ray tracing system design for idealized metasurface. We also have metasurfaces informed system design, and cascaded to co-optimized design. Time consuming aspect of design is simulation of nanostructures. We need to reduce loop time. For high-speed large area design, we have inverse design, and surrogate solver. We have combined optimization and network. We need large training set. Future work includes wide applicability and larger area. Component tolerancing should be linked to system tolerance. We have Monte Carlo study for tolerance analysis. Monte-Carlo simulation is the most popular and simplest method for nonlinear statistical tolerance analysis.

Ms. Maryvonne Chalony, Application Engineering Manager, Synopsys, presented the MetaOptic Designer, a fully automated commercial tool for metasurfaces optimization. The existing metalens design approach is semi-automatic, multi-domain approach.

Synopsys released in Sept. 2022, MetaOptic Designer, a fully automated tool with inverse design capability. It automatically generates metalens/metasurface layouts, RSoft CAD files for simulation, and GDS lines for fabrication. It reduces the level of knowledge and expertise required, shortens design cycle, and saves money and space. MetaOptic Designer determines the design parameters across each metasurface, and exports GDS and optimization results. We can also combine refractive lenses and metalenses.

This entry was posted in global semiconductor industry, Metalenses, Metamaterials, Photonics, Semiconductors, Silicon photonics and tagged Metalenses, Metamaterials.