Impact of updates to UL 1973 for stationary energy storage systems

CSA Group recently organized a seminar on assessing the impact of updates to UL 1973 for stationary energy storage systems.

Scott Daniels, Head of Power and Energy Storage, CSA Group, said CSA Group laboratories are Nationally Recognized Testing Laboratories (NRTL). Commercializing technologies may require new standards or modifications of the existing standards. CSA Group has reliable testing expertise across major industries around the world.

Solutions include consumer product evaluation, environmental testing, energy efficiency verification, electrical and functional safety, special inspection/field evaluation, electromagnetic compatibility (EMC) and wireless, cyber security, and certification. CSA Distributed Energy Resource Lab is a new state-of-art laboratories located at US headquarters site in Cleveland, Ohio. It offers services for power conversion systems, including inverters and converters, electric vehicle supply equipment (EVSE), including AC and DC EV chargers, and battery systems, including portable power, eMobility, and stationary.

Michael Becker, Compliance and Technical Specialist, Energy Storage, CSA Group, said that complex and long design cycles pose significant challenges when selecting Li-ion cell technologies to satisfy critical application metrics. He gave an example of Boeing 787 batteries. Boeing apparently failed to design batteries for most severe effects of a short ciruit that caused fire in a Japan Airlines plane parked in Boston, Jan. 2013.

Safer lithium-ion cathode chemistries hold on to their oxygen. Battery cell fires are initially fueled by liquid electrolyte and atmospheric Oxygen (O2). O2 is a “catalyst”, and oxide-based cathodes will release O2 at elevated temperatures. O2 evolving from cathodes at elevated temperatures makes fire suppression extremely challenging. We cannot use conventional O2 starvation fire suppression effectively since the battery cell fire is supplying its own catalyst. Lithium iron phosphate (LFP) is thermally stable.

Thermo-gravimetric analysis (TGA) is a very sensitive small scale located in a heated sealed chamber that is used to measure small samples and their respective behavior to increasing temperature. For example, a small wet sponge will become light as the water evaporates when the temperature is elevated.

There are app metrics such as APU battery on aircraft, time of use (ToU), portable electronics. CSA’s commercial subsidiaries provide expert testing, inspection, and certification services that enable manufacturers to demonstrate that their products are in compliance with applicable safety, environmental, and operating performance standards for global markets.

UL 1973 overview

The scope of UL 1973 covers battery systems that are intended to be used in stationary energy storage systems. It also includes battery systems used in light electric rail (LER) and vehicle auxiliary power (VAP) applications. As a safety standard, UL 1973 does not cover performance or reliability considerations.

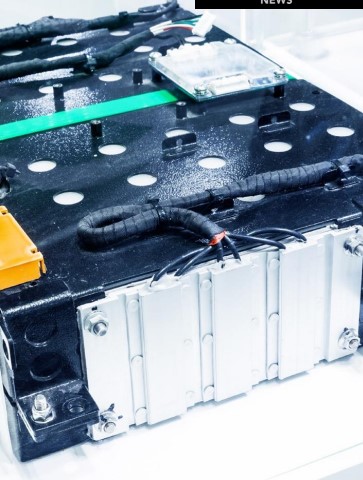

For a typical stationary energy storage system, scope of UL 1973 addresses requirements for cell, module, and battery rack up to battery management system (BMS). The scope does not include power conversion equipment or other system level components. The full energy storage system is covered under UL 9540.

When looking at UL 1973 updates for Li-ion cell requirements, UL 1973 2nd Edition states that secondary lithium cells could comply with UL 1973 under one of the following criteria:

- Compliance with UL 1642 in addition to the modifications under Exceptions No. 1-5 in 7.11.2.

- Compliance with test program in Appendix E of UL 1973.

UL 1973 3rd Edition stated that:

- Secondary lithium cells need to comply with the cell test program of Annex E.

- Lithium cell construction review required and documentation of cell components; needs to be designed to mitigate internal short circuit (criteria in 7.12.3).

So, what does this means for ESS manufacturers? Lithium cells certified to UL 1642 are not sufficient to meet UL 1973 requirements. Lithium cells are evaluated through a test program and in-depth construction review into cell internal components.

There are UL 1973 updates for repurposed cells and batteries. For UL 1973 2nd Edition, there are no specific requirements pertaining to repurposing of cells and batteries for use in stationary energy storage systems.

In UL 1973 3rd Edition, repurposed cells and batteries used in UL 1973 stationary energy storage systems need to have been processed in compliance with UL 1974. UL 1974 covers sorting and testing procedures for repurposed cells and batteries. A battery system built with EV batteries sorted using an approved process still needs to comply with UL 1973.

And, what does this means for ESS manufacturers? If you are using repurposed cells or batteries to build a battery system, ensure they have been processed through a UL1974 approved procedure. The end product battery system still needs to be evaluated to UL1973 requirements.

There are UL 1973 updates for lead acid and Ni-Cad requirements. In UL 1973 2nd Edition, there are minimal references to specific requirements for lead acid and Ni-Cad batteries; it was difficult to apply to lead-acid monoblocs. In UL 1973 3rd Edition, there were clarified requirements for lead acid and nickel cadmium batteries. Annex H “Alternative Approach was added for evaluating valve regulated or vented lead acid or nickel cadmium batteries. It creates a more focused test plan for these legacy technologies that can have simplified controls and may not use a BMS.

For ESS manufacturers, manufacturers of lead acid and Ni-Cad batteries can comply with UL 1973 without meeting all the requirements typical for a lithium-ion system. The stationary energy storage systems assembled on site using these technologies can still comply with UL 1973 and building fire code regulations.

There are UL 1973 updates for vehicle auxiliary power battery requirements. In UL 1973 2nd Edition, most references were specific to light electric rail (LER) applications; the only mention of vehicle auxiliary power (VAP) was in the title of the standard. It addressed mechanical testing for LER applications under Sections 25 through 27.

UL 1973 3rd Edition clarified scope to apply to VAP applications; it includes batteries used for recreational and other auxiliary vehicle power applications; and does not provide traction power. VAP batteries must meet mechanical testing of UL 1973, including vibration, shock, and crush (UL 2271/UL 2580 also referenced). For ESS manufacturers, Li-ion and other batteries used for VAP applications (RVs, truck refrigeration, etc.) need to comply with UL 1973 approved for use as VAP batteries.

Regarding clarifications for new battery technologies, UL 1973 2nd Edition contains some guidance for applying requirements to alternate battery chemistries, including flow and sodium-beta batteries. UL 1973 3rd Edition has added guidance on requirements for several new chemistry types, such as sodium ion, clarified testing on flow batteries in Annex C, and added Annex I “test program for mechanically rechargeable metal-air batteries”. ESS manufacturers that utilize some of these newer or evolving battery technologies have clarified guidance in UL 1973.

For functional safety requirements, UL 1973 2nd Edition contained functional safety requirements under Clauses 7.7 and 7.8. It was not clear if active protective device needed to meet functional safety requirements. It combined requirements for hardware and software requirements and did not specify level of protection (SIL/PL/ASIL).

UL 1973 3rd Edition clarified that all active protective devices (such as BMS) need to be evaluated to functional safety requirements. Unless safety analysis shows reduced risk, protective controls must meet minimum SIL 2, PL c, or ASIL C safety ratings. Hardware and software was relied upon for safety separated based on standards requirements to UL 991/UL1998, UL 60730-1, or CSA C22.2 No. 0.8. The ESS manufacturers need to ensure that any protective controls, such as the BMS, meet the updated requirements for functional safety.

UL 1973 updates for additional electrical tests has UL 1973 2nd Edition that says overcharge testing of Section 15 mainly focused on an increased charging voltage, but limited current to maximum charging rate. Over discharge testing of Section 17 was also based only on voltage limit with current limited to maximum discharging rate. Overload testing under short circuit test of Section 16 focused only on 85 percent of fuse rating, instead of BMS protection limit.

UL 1973 3rd Edition added new high-rate charge test in Section 16. Current supplied to the battery during charge was 20 percent above rating. It added new overload under discharge test in Section 18. Overload is to be performed just below BMS protection limit, and just above BMS protection limit, but below fuse rating. ESS manufacturers would need to comply with UL 1973 3rd Edition, and manufacturers will need to perform these additional tests.